Unraveling the Science of High-Temperature Adhesives

Unraveling the Science of High-Temperature Adhesives

Introduction:

As industries continue to push the boundaries of technological innovation, the demand for materials that can withstand extreme conditions has never been higher. High-temperature adhesives play a pivotal role in ensuring the structural integrity of components exposed to elevated temperatures. In this exploration of the characteristics of high-temperature adhesives, we delve into the nuanced world of epoxy-based materials, shedding light on their technological prowess and the intricate considerations involved in ensuring bond strength at elevated temperatures.

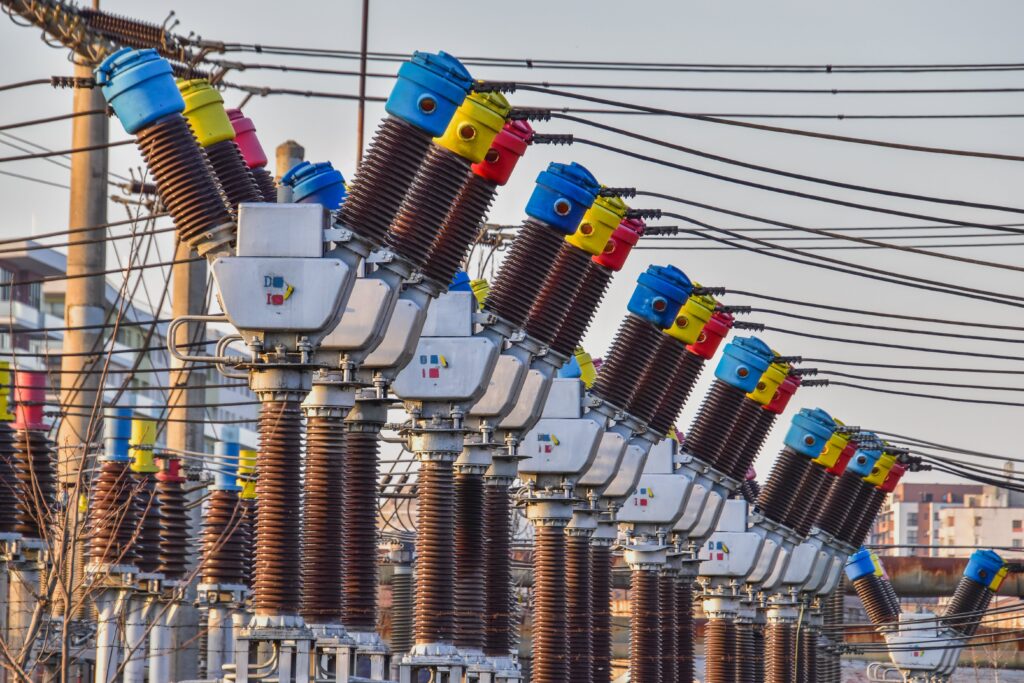

Photo by Dids .: https://www.pexels.com/photo/colorful-high-voltage-power-transformer-7867328/

Epoxy Resins: The Backbone of High-Temperature Adhesives:

At the heart of high-temperature adhesive technology lies epoxy resins. Epoxy adhesives are renowned for their exceptional bonding strength, versatility, and resistance to various environmental factors, making them the go-to choice for applications that require resilience under extreme temperatures.

Characteristics of High-Temperature Adhesives:

Thermal Stability:

High-temperature adhesives are designed to resist thermal degradation even in the harshest conditions. This is achieved by formulating the epoxy resin with additives that enhance its thermal stability, preventing the adhesive from breaking down or losing its adhesive properties at elevated temperatures.

Chemical Composition:

The chemical composition of high-temperature adhesives is carefully tailored to withstand the corrosive effects of extreme environments. Epoxy-based adhesives, in particular, exhibit superior resistance to chemicals, ensuring that the bond remains intact even when exposed to aggressive substances.

Curing Mechanism:

The curing mechanism of epoxy-based high-temperature adhesives is a critical aspect of their performance. These adhesives typically undergo a two-part curing process, involving the mixing of a resin and hardener. The curing temperature and time must be precisely controlled to achieve optimal cross-linking and bond strength.

Bond Strength Considerations:

The bond strength of high-temperature adhesives is paramount in applications where structural integrity is non-negotiable. However, achieving and maintaining this strength at elevated temperatures presents a unique set of challenges.

Temperature Ratings:

Manufacturers meticulously specify the temperature ratings of their high-temperature adhesives. This indicates the maximum temperature at which the adhesive can reliably maintain its bond strength. Applications exceeding these limits risk compromising the integrity of the bonded components.

Thermal Cycling:

Thermal cycling, the process of repeatedly subjecting the adhesive to alternating high and low temperatures, can strain the bond and lead to failure over time. Epoxy-based adhesives are engineered to mitigate the effects of thermal cycling, providing a stable and enduring bond even in the face of temperature fluctuations.

Testing at High Temperatures:

Ensuring the reliability of high-temperature adhesives requires rigorous testing under conditions that mimic real-world applications. Various testing methods are employed to assess bond strength, durability, and resistance to thermal stress:

Shear Testing:

Shear testing involves subjecting the bonded specimens to forces parallel to the adhesive interface. This test provides valuable insights into the adhesive’s ability to withstand mechanical stress at high temperatures.

Thermal Aging:

Thermal aging tests involve exposing the bonded samples to elevated temperatures for extended periods. This simulates the long-term effects of high-temperature exposure on the adhesive, helping identify potential weaknesses and vulnerabilities.

Failures at High Temperature:

While high-temperature adhesives are engineered to excel in extreme conditions, failures can occur, often with significant consequences. Witnessing these failures firsthand underscores the importance of understanding the limitations and proper application of these adhesives.

Thermal Overload:

Exceeding the specified temperature limits can result in thermal overload, causing the adhesive to degrade or lose its bond strength. This can lead to catastrophic failures in critical components, emphasizing the need for strict adherence to temperature guidelines.

Inadequate Surface Preparation:

Insufficient surface preparation can compromise the adhesive bond. Contaminants, improper cleaning, or inadequate roughening of surfaces can all contribute to weakened bonds, especially when exposed to high temperatures.

Conclusion:

The careful consideration of thermal stability, chemical resistance, and curing mechanisms ensures that these adhesives deliver unparalleled performance in extreme conditions. However, success hinges on understanding the intricacies of bond strength, conducting rigorous testing, and learning from the failures that can occur when pushing these materials to their limits. As we continue to advance in technology, the saga of high-temperature adhesives unfolds, presenting both challenges and opportunities for those at the forefront of innovation.

Amatech is a leading supplier of adhesive for high temperature applications. Amatech and Linkobond are the trademarks of Amatech company.