Thermally conductive compounds Formulation, Types and 6 Key Features

By – Dr. Mukesh Kumar Madhup

Amatech Innovation Pvt Ltd., Ahmedabad

1. Formulating Thermally Conductive Compounds

Polymeric materials generally have very low thermal conductivity. Various polymeric materials viz. epoxies, polyurethanes [PU], silicones are suitable for formulating thermally conductive compounds but have thermal conductivity in the range of 0.01 to 0.15 W/m-K. To be suitable for dissipation of heat, the compounds should be able to conduct heat at higher rate. To enhance thermal conductivity generally the composite materials are filled by ceramic materials which are having high thermal conductivity. The formulated compounds, subject to the design need, can be classified as thermally conductive but electrically insulative or both thermally as well as electrically conductive. We at Amatech, have both kinds of technologies to meet our customers need.

- Types of Thermally conductive compounds:

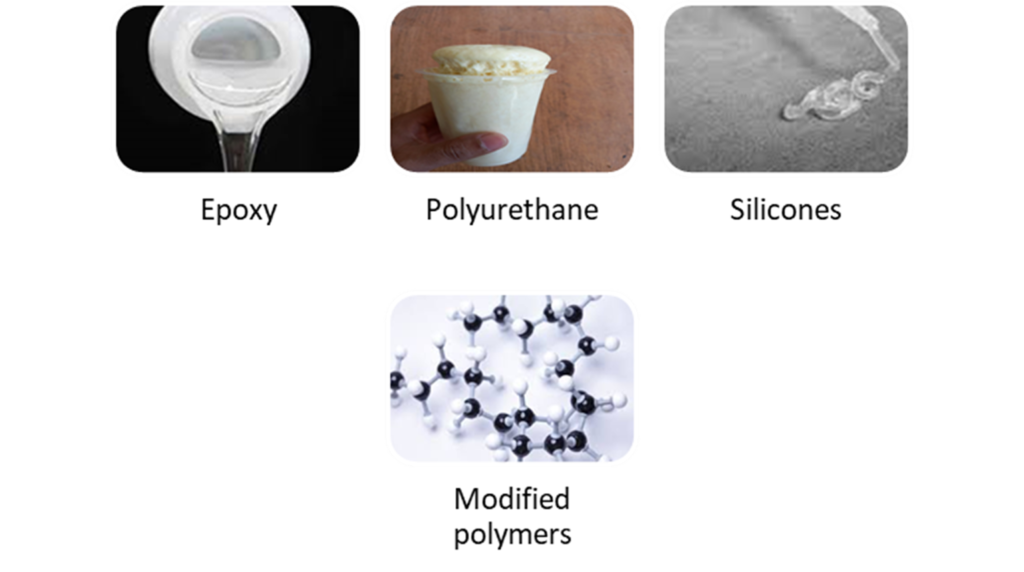

More commonly, following four types of thermally conductive materials are widely used in the industry, these are classified basis the type of backbone polymeric materials used.

Fig.1. Different polymeric backbone type used in thermally conductive compounds

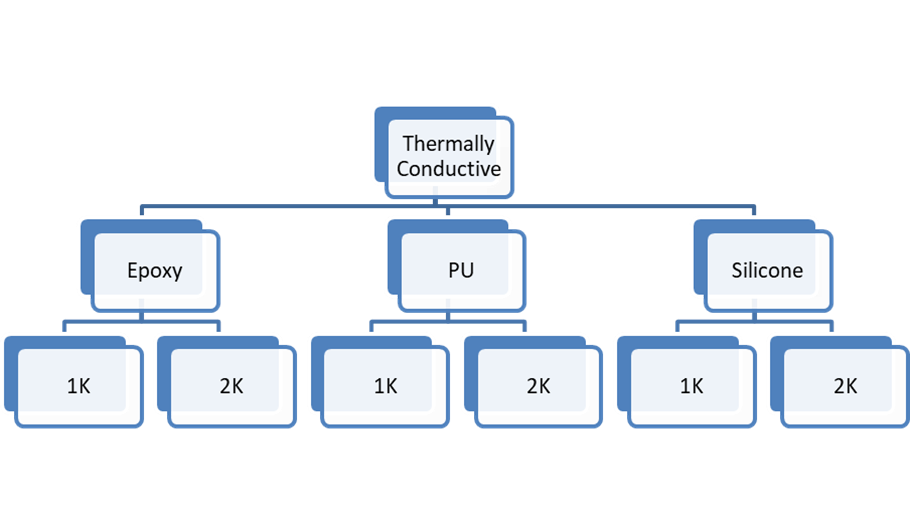

Fig.2. Classification of thermally conductive compounds based on resin and the number of components.

2.1 Various systems of thermally conductive compounds

2.1.1 1K System:

All 1K (single component) systems doesn’t require any mixing. These are available in for form of paste, solid or liquid forms. The advantage of 1K design is that you don’t need to mix two materials after weighing in a specifically given ratio; thereby it eliminates any error due to mixing ratio or calculations. Single component products are very simple design and user friendly epoxies, PU and silicones.

2.1.2 2K systems:

This system is very common and widely used in the industry. Two component (2K) systems are robust in design in terms of performance and durability. 2K systems are reaction type materials which are separately packed in two different containers. Containers possessing pre-weighed amount are also available which saves time and resources of users.

2.2. Types of Polymer

- Epoxy: Various types of epoxies including Bisphenol A or Novolac types are used depending up on the type of applications, generally cured by polyamines or polyamides.

- Polyurethanes: These are isocyanate cured compounds having various types of resin chemistries.

- Silicones: These are special types or siloxane resins normally can withstand higher temperature and provides higher flexibility compared to epoxies or PU.

The adhesive designed using silicones backbone are elastomeric materials with high flexibility and temperature resistance features. Moisture cure technology is used in case of single component designs. Single component silicone based mateials are also of grease type which simply relieves the system from heat by helping in dissipation without drying or forming any film. Silicon based materials are better in weather resistance and thermal shock performances.

- Features of Thermally conductive compounds

Thermally conductive compounds are expected to provide high performance with durability and not losing on properties through the life cycle. Various long term testing are performed to ascertain that the developed compounds can meet the expected life and application parameters. Here are listed few features of the thermally conductive compounds.

Fig.3. Features of thermally conductive compounds

- High Bond Strength

High bond strength is one of the most important features for durable materials efficiency of a thermally conductive compounds. In general, all 2K epoxy and PU compounds are designed for high bond strength for various substrates including metals and non-metallics.

2. Chemical resistance

Various applications of the thermally conductive compounds come in contact with the chemicals or salts. For durable protection and efficient work of thermally conductive compounds, it should be chemically resistant.

3. High Thermal Resistance

Since these compounds come in continuous exposure of heating of the pumps, electronic devices or frictions including external heating sources, the compounds are expected to withstand high thermal resistance during heat exposure.

4. Thermal Shock Resistance

Thermal shock is basically created due to high heating and sudden cooling. Various applications of thermally conductive compounds need the ability to withstand a sudden change in temperature without crack or degradation for durable protection and heat sinking.

5. Good Pot Life and Applicability

This feature is key for application for a thermally conductive compound. After mixing of two components materials, the user should have sufficient time [pot life] to apply the materials before it gets gelled. Good flow, leveling and finish is another application requirement.

6. Long Lasting Thermal Conductivity

Since thermally conductive material provides sinking of heat, once applied it should be durable enough to provide continuous protection of the part for long period.

- Applications

These materials are widely applied in automotive, optical, optoelectronics, medical and household appliances, and power and electronics industries.

- Testing and Certifications:

Fire retardancy property is the critical parameter in the design and application of any thermally conductive compounds. Since the electrical and electronics parts are prone for short circuits and sparks, the compound should not propagate the fire as well as it should not be combustible, rather it should help in retarding the any potential fire. Following are the two important test for fire related ratings:

- UL94-0

Potting or encapsulating compounds are tested for fire retardancy and self-extinguishing properties. The other ratings of UL -1 and UL-2 of these filled compounds are tested for elevated temperatures.

5.2 FAR 25.853 (a) for Flame Retardant property

Fire retardancy property under FAR 25.853 (a) is tested for vertical and horizontal burn test. This test is used for determining material’s capability for eclosed areas where components in have to be resist the fire having potting and encapsulation materials. Burn rate, burn length and time are recorded in this test.

- Material Safety compliance

- RoHS compliance: Amatech formulations are compliant to RoHS during design state itself. The products shouldn’t contain materials specified in the RoHS list of restricted chemicals.

- REACH: To maintain high level of safety and reduced hazard level, industry looks for complying the REACH requirements where, the thermally conductive materials shouldn’t contains materials specified in the REACH compliance to protect human health and the environment.

- The advantages of thermally conductive adhesive

Here are the list of advantages for using Amatech’s thermally conductive compounds

- Productivity and efficiency can be improved suiting your application.

- Amatech adhesives for thermal applications are designed for various range of conductivity to effectively dissipate the heat with high adhesive bonding with substrate.

- Your components performance can be improvement due to high heat dissipation; it improves total life of the products and improved efficiency.

- Good gap filling with high bonding which provides continuity of the body and assembly.

- Provides high mechanical bonding.

- Good alignment in various electricals and electronics applications.

- A safe for handling and uses.

- Compliances as per various standards

- Being available in various viscosities and density, your products can be bonded between two substrates.

These materials are designed to maintain bondline thickness, providing excellent thermal path to the heat generated. Amatech’s 1K materials are also designed for application by screen printing and auto dispensing methods for various electronics parts.

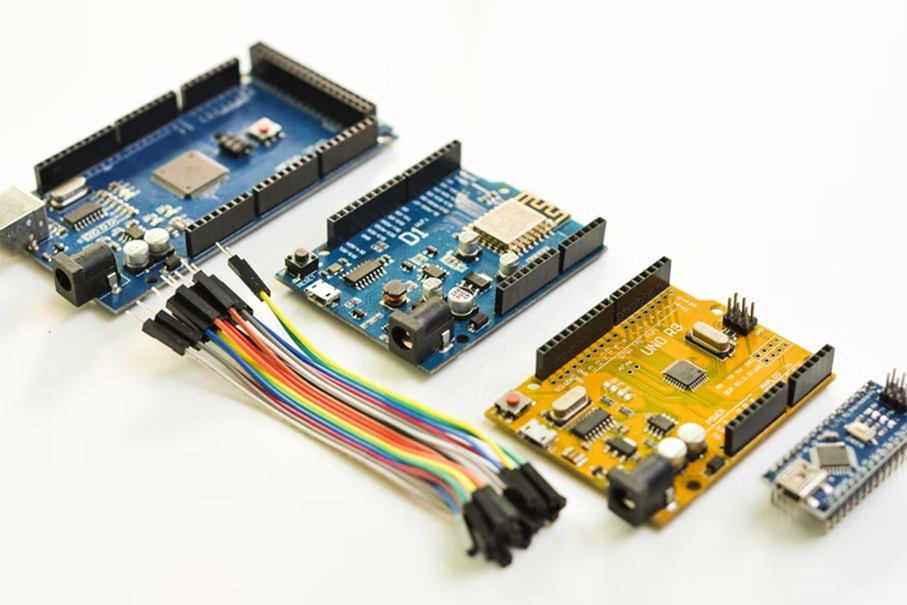

Fig.4 Electronics circuit boards and components which needs thermally conductive compounds, Photo by Frank Wang on Unsplash

Electric circuit boards and components need effective heat sinking to keep the board cool and work efficiently.

Fig.5. Application illustrations of thermally conductive materials, Photo by Olivier Collet on Unsplash

One thought on “Thermally conductive compounds Formulation, Types and 6 Key Features”